SK Enterprises Products – Our commitment to quality at SK Enterprises is not just a statement, but a rigorous practice embedded in every stage of our production and supply chain. Each product undergoes stringent quality checks to ensure it meets international standards before it reaches our clients. This approach guarantees reliability, durability, and performance, making SK Enterprises a trusted name in the industrial and manufacturing sector. By implementing comprehensive testing procedures, we minimize defects, enhance safety, and ensure compliance with regulatory norms, thereby building confidence among our customers. The focus on quality is further reinforced by adherence to certifications from reputed authorities, which serve as a testament to our dedication. Industries across India and abroad rely on SK Enterprises for high-quality components and machinery, knowing that every item has been meticulously verified. The quality assurance process not only safeguards customer interests but also strengthens our brand reputation as a reliable and consistent supplier. SK Enterprises continues to invest in advanced testing equipment and skilled personnel to uphold this quality promise, ensuring long-term sustainability and growth.

Stringent Testing Procedures for Reliable Products

At SK Enterprises, every product is subjected to a series of stringent testing procedures designed to detect even the smallest defects. These procedures include material testing, performance analysis, and stress testing under extreme conditions. For example, mechanical components are tested for tensile strength, fatigue resistance, and durability according to international standards such as ISO 9001 quality management guidelines. Electrical equipment undergoes rigorous inspection for insulation, conductivity, and heat resistance to ensure operational safety and efficiency. Additionally, chemical composition tests are conducted to verify the purity and reliability of raw materials. These measures not only ensure compliance with legal and industrial norms but also protect end-users from potential hazards. By maintaining detailed documentation of every testing process, SK Enterprises provides traceability and accountability, which are critical for industrial clients who prioritize safety and reliability. Continuous monitoring and upgrading of testing protocols ensure that SK Enterprises products remain at the forefront of quality assurance in the manufacturing sector.

Certified Products for Industry Confidence

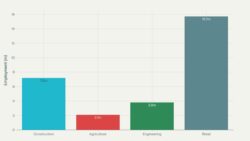

Certifications play a crucial role in establishing trust and confidence in the products supplied by SK Enterprises. Each product line undergoes certification by recognized authorities to ensure compliance with global quality and safety standards. For instance, electrical and electronic components are certified according to CE marking regulations, while mechanical parts may carry certifications aligned with ASTM International standards. These certifications are not just regulatory requirements; they are an assurance to clients that our products meet rigorous testing criteria and are safe for industrial applications. By integrating certified processes into our manufacturing workflow, SK Enterprises minimizes production risks and enhances customer satisfaction. Moreover, third-party certification audits provide independent validation of product quality, further strengthening the credibility of our offerings. Industries across sectors, including manufacturing, construction, and engineering, prefer certified SK Enterprises products because they reduce operational risks, improve efficiency, and ensure long-term reliability.

Our Journey: How SK Enterprises Grew from a Local Supplier to a Nationally Recognized Brand

Our Journey: How SK Enterprises Grew from a Local Supplier to a Nationally Recognized Brand

Advanced Quality Management Systems in Place

To sustain high standards, SK Enterprises has implemented advanced quality management systems (QMS) across all its operations. These systems are designed to standardize processes, monitor performance, and continuously improve product quality. By leveraging digital tools and real-time monitoring software, SK Enterprises can detect deviations and address potential issues proactively. The QMS framework aligns with international best practices, including ISO 9001 certification, which emphasizes customer satisfaction, risk management, and process optimization. Staff training is a vital component of our QMS, ensuring that employees at every level understand the importance of quality and adhere to prescribed standards. Through these integrated systems, SK Enterprises achieves consistency in production, reduces wastage, and enhances overall operational efficiency. Clients benefit from predictable performance, reduced downtime, and dependable product quality, which is especially critical in sectors that rely on precision and high standards.

Welcome to SK Enterprises India – Delivering Quality Products and Industrial Solutions Nationwide

Welcome to SK Enterprises India – Delivering Quality Products and Industrial Solutions Nationwide

Continuous Improvement and Industry Leadership

SK Enterprises is committed to continuous improvement, recognizing that quality is a dynamic target that evolves with technology and industry requirements. Regular audits, customer feedback, and innovation-driven testing methods are employed to refine products and processes continually. The company actively monitors global industrial trends and updates its standards accordingly, ensuring products not only meet but exceed client expectations. Research collaborations with academic institutions and industrial bodies help SK Enterprises integrate cutting-edge techniques in material science, manufacturing, and quality assurance. By fostering a culture of excellence, transparency, and accountability, SK Enterprises has established itself as an industry leader trusted for high-quality, certified products. Clients can confidently rely on SK Enterprises for machinery, components, and equipment that meet rigorous performance criteria, comply with regulatory norms, and deliver long-term reliability. The commitment to quality is not just a promise but an operational philosophy embedded in every product we deliver.